Project Showcase

View summaries of Tauber team projects from recent years.

Sort by year, sponsoring company, industry, or project solution.

View summaries of Tauber team projects from recent years.

Sort by year, sponsoring company, industry, or project solution.

Tesla’s rapid growth will require considerable scaling and streamlining of its supply chain processes over the next few years. To this end, the Tauber team was tasked with exploring opportunities for efficiency with regard to the flow of inbound parts for future production.

The team identified the key gaps which most affect the company’s long-term strategy and ability to scale, and then created a decision support system based on linear programming and other operations research techniques, aimed at optimizing the flow of parts inbound from the supplier to the production line.

With full implementation, the expected annual savings to Tesla is over $10M.

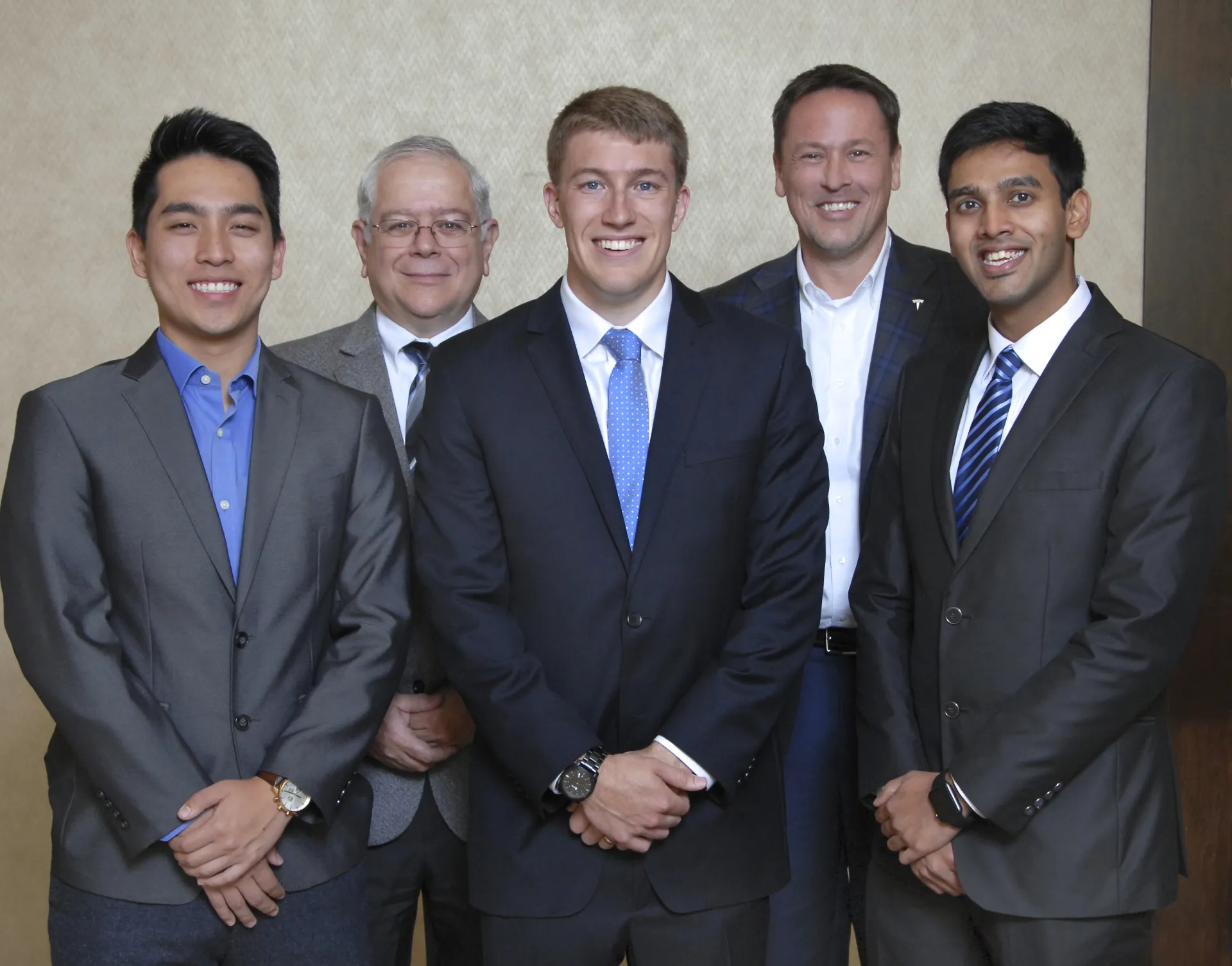

Student Team:

Mukund Varma A.T – Master of Business Administration

Osbert Fu – EGP (MSE Industrial and Operations Engineering)

Brian McGuiness – Master of Business Administration

Project Sponsors:

Adam Plumpton – VP Worldwide Logistics

Mike Polich – Director, Worldwide Component Logistics

Ravi Vengadam – Sr. Staff Engineer, Material Flow Engineering

Faculty Advisors:

Yavuz Bozer – College of Engineering

Roman Kapuscinski - Ross School of Business