Project Showcase

View summaries of Tauber team projects from recent years.

Sort by year, sponsoring company, industry, or project solution.

View summaries of Tauber team projects from recent years.

Sort by year, sponsoring company, industry, or project solution.

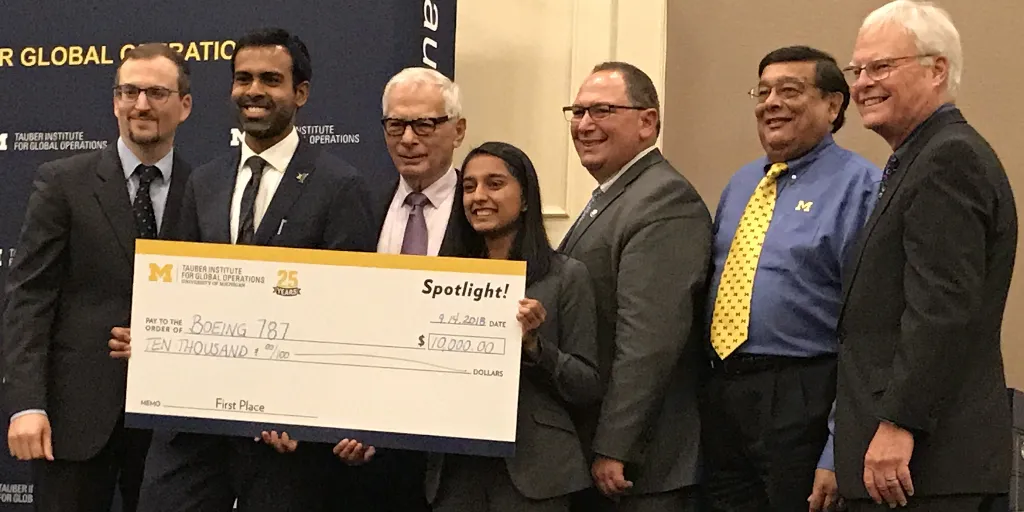

The Boeing 787 Dreamliner is one of the most innovative products that The Boeing Company has ever produced, and the aircraft faces ever-increasing demand from commercial airlines. Mechanics building the aircraft complete work using premade kits; however, these kits are not always fully stocked with the parts needed to complete work. The purpose of this project is to optimize the kitting process to reduce the amount of time that the mechanics spend in non-value added activities, such as locating the correct tools and parts needed to complete a job, maximizing the time mechanics spend on the airplane, and reducing delays in production.

Student Team:

Yatri Patel – EGL (BSE Mechanical Engineering/MSE Industrial and Operations Engineering)

Kartik Raju – Master of Business Administration

Project Sponsors:

Michael Jordan – Manager, 787 Manufacturing Engineering

Miles Mason – Manager, 787 Manufacturing Engineering

Zachary Tyree – Senior Manager, 787 Manufacturing Engineering

Faculty Advisors:

Prakash Sathe – College of Engineering

Andrew Wu – Ross School of Business